Applications for Industrial Vacuum Systems

“Industrial vacuum” is a blanket term that refers to different systems that use pressure and vacuum to transport material away from work areas to a repository where it can be eliminated. Industrial vacuum systems come in a variety of configurations and can be customized to meet the needs of various industries and applications.

“Industrial vacuum” is a blanket term that refers to different systems that use pressure and vacuum to transport material away from work areas to a repository where it can be eliminated. Industrial vacuum systems come in a variety of configurations and can be customized to meet the needs of various industries and applications.

Uses and Industries

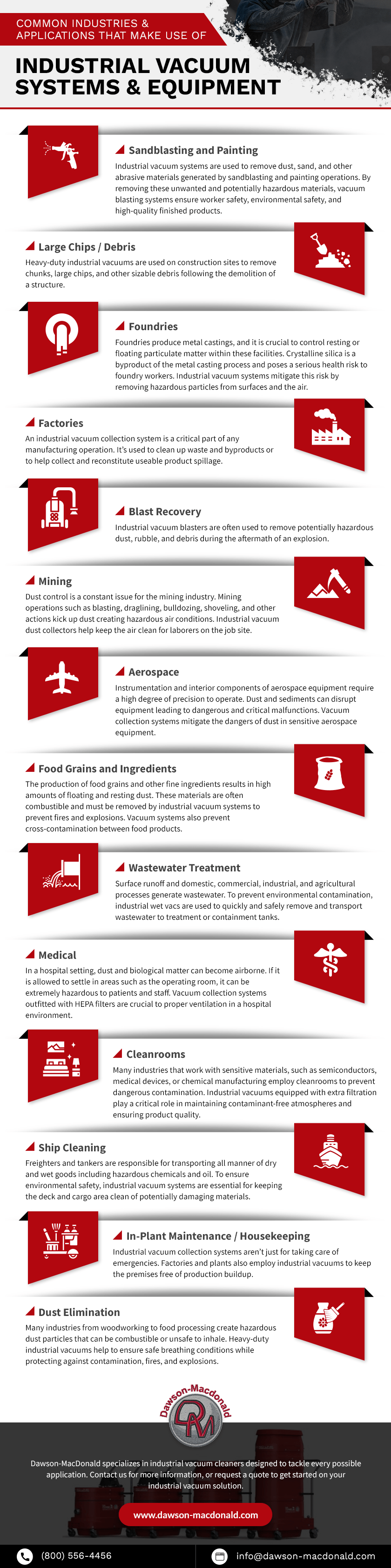

Industrial vacuum systems are used across a wide variety of industries and applications, including:

Sandblasting and Painting

Industrial vacuum systems are used to remove dust, sand, and other abrasive materials generated by sandblasting and painting operations. By removing these unwanted and potentially hazardous materials, vacuum blasting systems ensure worker safety, environmental safety, and high-quality finished products.

Large Chips / Debris

Heavy-duty industrial vacuums are used on construction sites to remove chunks, large chips, and other sizable debris following the demolition of a structure.

Foundries

Foundries produce metal castings, and it is crucial to control resting or floating particulate matter within these facilities. Crystalline silica is a byproduct of the metal casting process and poses a serious health risk to foundry workers. Industrial vacuum systems mitigate this risk by removing hazardous particles from surfaces and the air.

Factories

An industrial vacuum collection system is a critical part of any manufacturing operation. It’s used to clean up waste and byproducts or to help collect and reconstitute useable product spillage.

Blast Recovery

Industrial vacuum blasters are often used to remove potentially hazardous dust, rubble, and debris during the aftermath of an explosion.

Mining

Dust control is a constant issue for the mining industry. Mining operations such as blasting, draglining, bulldozing, shoveling, and other actions kick up dust creating hazardous air conditions. Industrial vacuum dust collectors help keep the air clean for laborers on the job site.

Aerospace

Instrumentation and interior components of aerospace equipment require a high degree of precision to operate. Dust and sediments can disrupt equipment leading to dangerous and critical malfunctions. Vacuum collection systems mitigate the dangers of dust in sensitive aerospace equipment.

Food Grains and Ingredients

The production of food grains and other fine ingredients results in high amounts of floating and resting dust. These materials are often combustible and must be removed by industrial vacuum systems to prevent fires and explosions. Vacuum systems also prevent cross-contamination between food products.

Wastewater Treatment

Surface runoff and domestic, commercial, industrial, and agricultural processes generate wastewater. To prevent environmental contamination, industrial wet vacs are used to quickly and safely remove and transport wastewater to treatment or containment tanks.

Medical

In a hospital setting, dust and biological matter can become airborne. If it is allowed to settle in areas such as the operating room, it can be extremely hazardous to patients and staff. Vacuum collection systems outfitted with HEPA filters are crucial to proper ventilation in a hospital environment.

Cleanrooms

Many industries that work with sensitive materials, such as semiconductors, medical devices, or chemical manufacturing employ cleanrooms to prevent dangerous contamination. Industrial vacuums equipped with extra filtration play a critical role in maintaining contaminant-free atmospheres and ensuring product quality.

Ship Cleaning

Freighters and tankers are responsible for transporting all manner of dry and wet goods including hazardous chemicals and oil. To ensure environmental safety, industrial vacuum systems are essential for keeping the deck and cargo area clean of potentially damaging materials.

In-Plant Maintenance / Housekeeping

Industrial vacuum collection systems aren’t just for taking care of emergencies. Factories and plants also employ industrial vacuums to keep the premises free of production buildup.

Dust: Concrete Dust, Abrasive Dust, Wood Dust, Plastic Dust, Fine/Dry dust, Combustible Dust

Many industries from woodworking to food processing create hazardous dust particles that can be combustible or unsafe to inhale. Heavy-duty industrial vacuums help to ensure safe breathing conditions while protecting against contamination, fires, and explosions.

Industrial Vacuum Systems from Dawson-Macdonald

Various types of industrial dust collection systems are used across several industries to create clean, safe working environments. Dawson-MacDonald specializes in industrial vacuum cleaners designed to tackle every possible application. Contact us for more information, or request a quote to get started on your industrial vacuum solution.

Learn More

Learn More

Comments are closed