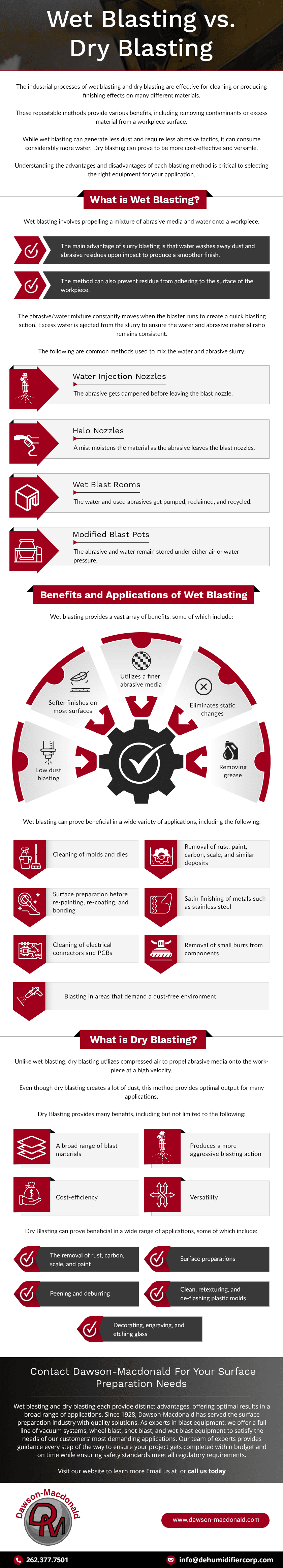

Wet Blasting vs. Dry Blasting

Leave a CommentThe industrial processes of wet blasting and dry blasting are effective for cleaning or producing finishing effects on many different materials. These repeatable methods provide various benefits, including removing contaminants or excess material from a workpiece surface.

While wet blasting can generate less dust and require less abrasive tactics, it can consume considerably more water. Dry blasting can prove to be more cost-effective and versatile. Understanding the advantages and disadvantages of each blasting method is critical to selecting the right equipment for your application.

What is Wet Blasting?

Wet blasting involves propelling a mixture of abrasive media and water onto a workpiece. The main advantage of slurry blasting is that water washes away dust and abrasive residues upon impact to produce a smoother finish. The method can also prevent residue from adhering to the surface of the workpiece.

The abrasive/water mixture constantly moves when the blaster runs to create a quick blasting action. Excess water is ejected from the slurry to ensure the water and abrasive material ratio remains consistent.

The following are common methods used to mix the water and abrasive slurry:

- Water Injection Nozzles: The abrasive gets dampened before leaving the blast nozzle.

- Halo Nozzles: A mist moistens the material as the abrasive leaves the blast nozzles.

- Wet Blast Rooms: The water and used abrasives get pumped, reclaimed, and recycled.

- Modified Blast Pots: The abrasive and water remain stored under either air or water pressure.

Benefits of Wet Blasting

Wet blasting provides a vast array of benefits, some of which include:

- Low dust blasting

- Softer finishes on most surfaces

- Utilizes a finer abrasive media

- Eliminates static changes

- Removing grease

Applications of Wet Blasting

Wet blasting can prove beneficial in a wide variety of applications, including the following:

- Cleaning of molds and dies

- Removal of rust, paint, carbon, scale, and similar deposits

- Surface preparation before re-painting, re-coating, and bonding

- Satin finishing of metals such as stainless steel

- Cleaning of electrical connectors and PCBs

- Removal of small burrs from components

- Blasting in areas that demand a dust-free environment

What is Dry Blasting

Unlike wet blasting, dry blasting utilizes compressed air to propel abrasive media onto the workpiece at a high velocity. Even though dry blasting creates a lot of dust, this method provides optimal output for many applications.

Benefits of Dry Blasting

Dry Blasting provides many benefits, including but not limited to the following:

- A broad range of blast materials

- Produces a more aggressive blasting action

- Cost-efficiency

- Versatility

Applications of Dry Blasting

Dry Blasting can prove beneficial in a wide range of applications, some of which include:

- The removal of rust, carbon, scale, and paint

- Surface preparations

- Peening and deburring

- Clean, retexturing, and de-flashing plastic molds

- Decorating, engraving, and etching glass

Contact Dawson-Macdonald For Your Surface Preparation Needs

Wet blasting and dry blasting each provide distinct advantages, offering optimal results in a broad range of applications.

Since 1928, Dawson-Macdonald has served the surface preparation industry with quality solutions. As experts in blast equipment, we offer a full line of vacuum systems, wheel blast, shot blast, and wet blast equipment to satisfy the needs of our customers’ most demanding applications. Our team of experts provide guidance every step of the way to ensure your project gets completed within budget and on time while ensuring safety standards meet all regulatory requirements.

Contact us today or request a quote to learn more about the differences between wet blasting and dry blasting to determine which method is best for your specific application.

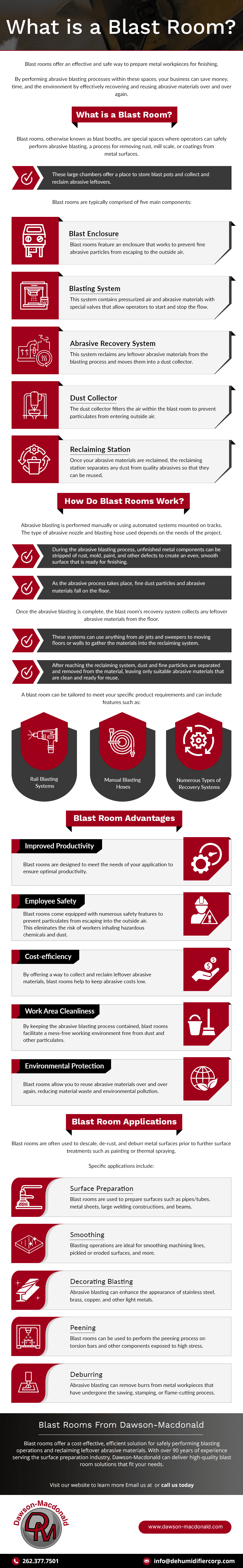

What is a Blast Room?

Leave a CommentBlast rooms offer an effective and safe way to prepare metal workpieces for finishing. By performing abrasive blasting processes within these spaces, your business can save money, time, and the environment by effectively recovering and reusing abrasive materials over and over again. In this blog, we’ll take a closer look at blast rooms, including how they work as well as their key benefits and applications.

What Is a Blast Room?

Blast rooms, otherwise known as blast booths, are special spaces where operators can safely perform abrasive blasting, a process for removing rust, mill scale, or coatings from metal surfaces. These large chambers offer a place to store blast pots and collect and reclaim abrasive leftovers.

Blast rooms are typically comprised of five main components:

- Blast enclosure. Blast rooms feature an enclosure that works to prevent fine abrasive particles from escaping to the outside air.

- Blasting system. This system contains pressurized air and abrasive materials with special valves that allow operators to start and stop the flow.

- Abrasive recovery system. This system reclaims any leftover abrasive materials from the blasting process and moves them into a dust collector.

- Dust collector. The dust collector filters the air within the blast room to prevent particulates from entering outside air.

- Reclaiming station. Once your abrasive materials are reclaimed, the reclaiming station separates any dust from quality abrasives so that they can be reused.

How Do Blast Rooms Work?

Abrasive blasting is performed manually or using automated systems mounted on tracks. The type of abrasive nozzle and blasting hose used depends on the needs of the project. During the abrasive blasting process, unfinished metal components can be stripped of rust, mold, paint, and other defects to create an even, smooth surface that is ready for finishing. As the abrasive process takes place, fine dust particles and abrasive materials fall on the floor.

Once the abrasive blasting is complete, the blast room’s recovery system collects any leftover abrasive materials from the floor. These systems can use anything from air jets and sweepers to moving floors or walls to gather the materials into the reclaiming system. After reaching the reclaiming system, dust and fine particles are separated and removed from the material, leaving only suitable abrasive materials that are clean and ready for reuse.

A blast room can be tailored to meet your specific product requirements and can include features such as rail blasting systems, manual blasting hoses, and numerous types of recovery systems.

Blast Room Advantages

Blast rooms provide the following advantages:

- Improved productivity. Blast rooms are designed to meet the needs of your application to ensure optimal productivity.

- Employee safety. Blast rooms come equipped with numerous safety features to prevent particulates from escaping into the outside air. This eliminates the risk of workers inhaling hazardous chemicals and dust.

- Cost-efficiency. By offering a way to collect and reclaim leftover abrasive materials, blast rooms help to keep abrasive costs low.

- Work area cleanliness. By keeping the abrasive blasting process contained, blast rooms facilitate a mess-free working environment free from dust and other particulates.

- Environmental protection. Blast rooms allow you to reuse abrasive materials over and over again, reducing material waste and environmental pollution.

Blast Room Applications

Blast rooms are often used to descale, de-rust, and deburr metal surfaces prior to further surface treatments such as painting or thermal spraying. Specific applications include:

- Surface preparation. Blast rooms are used to prepare surfaces such as pipes/tubes, metal sheets, large welding constructions, and beams.

- Smoothing. Blasting operations are ideal for smoothing machining lines, pickled or eroded surfaces, and more.

- Decorating blasting. Abrasive blasting can enhance the appearance of stainless steel, brass, copper, and other light metals.

- Peening. Blast rooms can be used to perform the peening process on torsion bars and other components exposed to high stress.

- Deburring. Abrasive blasting can remove burrs from metal workpieces that have undergone the sawing, stamping, or flame-cutting process.

Blast Rooms From Dawson-Macdonald

Blast rooms offer a cost-effective, efficient solution for safely performing blasting operations and reclaiming leftover abrasive materials. With over 90 years of experience serving the surface preparation industry, Dawson-Macdonald can deliver high-quality blast room solutions that fit your needs. For more information about our products and capabilities, contact us or request a quote today.