Blog

Wet Blasting vs. Dry Blasting

Leave a CommentThe industrial processes of wet blasting and dry blasting are effective for cleaning or producing finishing effects on many different materials. These repeatable methods provide various benefits, including removing contaminants or excess material from a workpiece surface. While wet blasting can generate less dust and require less abrasive tactics, it can consume considerably more water. […]

What is a Blast Room?

Leave a CommentClick to Expand Blast rooms offer an effective and safe way to prepare metal workpieces for finishing. By performing abrasive blasting processes within these spaces, your business can save money, time, and the environment by effectively recovering and reusing abrasive materials over and over again. In this blog, we’ll take a closer look at blast […]

Glass Bead vs. Aluminum Oxide Abrasives

Leave a CommentThe abrasive you choose for your surface preparation project will dramatically impact the final finish and appearance of your product, as well as the efficiency and cost of your project. Two common abrasives, glass bead and aluminum oxide abrasives, offer different results and have optimal uses in different applications. Read on to learn more about […]

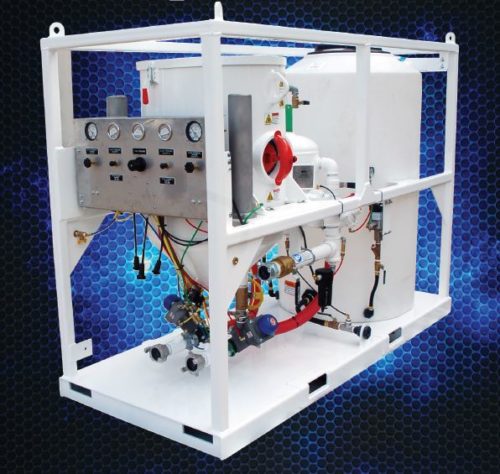

How to Automate Your Surface Preparation Process

Leave a CommentAutomating the surface preparation process includes reducing labor costs, improving quality control, and reducing manufacturing time. Automating the process also eliminates manual labor, which can be dangerous and lead to injuries. In addition, automated surface preparation machines are more consistent and accurate than manual labor, resulting in better-quality products. Dawson-McDonald Co., Inc. is a surface […]

How Dust Collection Systems Can Improve Your Workplace

Leave a CommentSeveral manufacturing processes generate by-products in the form of dust and other fine particulate matter. These applications need reliable dust collection solutions to ensure safe working conditions and improved air quality. Before choosing a dust collection system to install, it’s important to know how these systems work, the different types available, the benefits they offer, […]

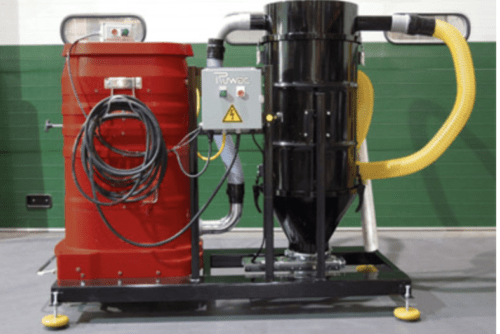

Benefits of Industrial Vacuum Systems

Leave a CommentIndustrial vacuum systems are essential equipment across various industries to optimize operational efficiency, which benefits your employees, customers, and bottom line. Industrial vacuum systems ensure cleanliness not only for visual purposes but also to promote the health and safety of workers and comply with environmental standards. For these reasons, it’s important to select and maintain […]

A Look at Ruwac Vacuums

Leave a CommentWhenever you need to tackle pollution at a workplace or on your property caused by dust and other substances, you need equipment that does a thorough job. Ruwac vacuums have been proven reliable for years now, and they are the preferred option by a majority of industries. Not only do Ruwac vacuums do a perfect […]

A Look at the Different Types of Blasting Machinery

Leave a CommentBlasting machines are designed to propel abrasive media toward the surface of a workpiece at high speeds. This process can result in a smoother or more textured surface, which improves the workability of the workpiece in downstream processing operations and/or enhances the performance of the workpiece in its intended application. There are many types of […]

A Brief Intro to Steel Abrasives

Leave a CommentSteel abrasives are a type of media used in blasting equipment. They are available in two forms: shot and grit. Steel shot consists of spherically shaped particles, while sheet grit consists of irregularly shaped particles. They can be used to remove unwanted materials (e.g., rust, paint, and scale) from the surface of a workpiece, to […]

Applications for Industrial Vacuum Systems

Leave a Comment“Industrial vacuum” is a blanket term that refers to different systems that use pressure and vacuum to transport material away from work areas to a repository where it can be eliminated. Industrial vacuum systems come in a variety of configurations and can be customized to meet the needs of various industries and applications. Uses and […]