Wet Blast Equipment Cabinets

Wet blast equipment cabinets have become increasingly popular as companies search for more efficient and effective ways to clean their products. Wet blasting provides a way to quickly and thoroughly clean items using a mixture of water and abrasive materials.

Are you looking for a safe and efficient way to blast paint and other debris off your equipment? A wet blasting cabinet from Dawson-Macdonald is the perfect solution! With a wet blast cabinet, you can quickly and easily clean your equipment without worrying about mess or safety risks.

What is wet blasting?

Wet blasting is a method of finishing delicate, precision-made components Using water and abrasives. The water as a protective layer minimizes the embedding risk, facilitates the use of very fine abrasives, uses low volumes, and produces a superior surface finish.

Abrasive media is usually mixed with water at 10-40% for wet blasting. With the blast gun, the slurry is pumped into the nozzle and compressed air to accelerate it to a high velocity. Be it cleaning, surface smoothing, coating preparation, cosmetic surface texturing, or peening; the blast media impact creates the desired effect.

Advantages of wet blasting

The following are the advantages you get when you use a wet abrasive blasting cabinet:

- A major advantage of this product is that it is gentle. ATEX regulations about explosive atmospheres are not required since the process produces no dust, preventing electrostatic issues.

- It does not cause media impingement, a problem associated with dry blasting that can embed media particles into the surface, compromising surface quality.

- The versatility allows different media concentrations and blast intensities to be easily adjusted to accommodate other materials and geometric structures to prevent damage to parts.

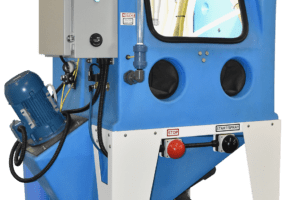

Dawson – Macdonald’s Wet Blasting Cabinets

Dawson-Macdonald Co., Inc.’s wet blast equipment uses the least amount of water to provide the best performance. You won’t have to worry about excessive moisture damaging your surfaces because they’ll be kept clean and free of contaminants.

Our wet blast equipment cabinets offer liquid abrasive systems utilizing their design urethane vortex submerged pump for heavy-duty use, extended wear, broad range concentration, and continuous cycle applications.

Each system is driven by an oversized motor-driven pump that produces the slurry required by the nozzles. Our finishes range from mild cleaning and profiling to de-burring and oxidation, as well as paint, oil, and scale removal using aggressive abrasives.

As part of Dawson – Macdonald’s range of wet blast equipment cabinets, we can offer the following equipment:

WT60SS Turntable

This wet blasting cabinet is made of stainless steel with a 60” x 60” interior, 47” W x 34” H base swing door with a 36” or 44” optional turntable. This wet blast equipment cabinet will help you eliminate manual or dry blasting, chemical use, disposal, and simultaneous applications.

WT36SS

Featuring a 36″ x 36″ interior and a 24″ W x 24″ H base swing door, this product allows for deep cleaning without embedded abrasives and ensures dust-free production.

WT36SS Vertical Door

The product has an interior dimension of 36″ x 36″ and an exterior dimension of 24″ W x 24″ H, as well as a vertical door width of 24″ x 24″. It reduces dust and warping during production and provides deep cleaning by combining blasting, shot blasting, and washing.

WT Force 3.36

Our proprietary high-concentration pumping system achieves an even finish, following industry standards regarding our closed-loop filtered rinsing process.

Our wet abrasive blasting cabinet ensures dust-free blasting and rinsing. This rotationally molded cabinet is durable and corrosion-proof and designed to resist corrosion.

Keeping your parts clean and polished is our expertise

Dawson-Macdonald provides top-of-the-line wet blast equipment cabinets that are ideal for any purpose. As a trusted name in the business, we guarantee that you’re acquiring the finest equipment for your demands.

Our experienced team is here to help you choose the right wet blasting cabinet for your application. So if you’re ready to buy a wet blast equipment cabinet, contact us today. We’ll be happy to assist you.